Spin-on carbon (SoC) hardmasks are an increasingly key component of the micro-chip fabrication process. They are used to improve the resists’ selectivity to silicon during plasma etching, and as chip architectures become increasingly complex they are increasingly used to improve the aspect ratio of features in silicon.

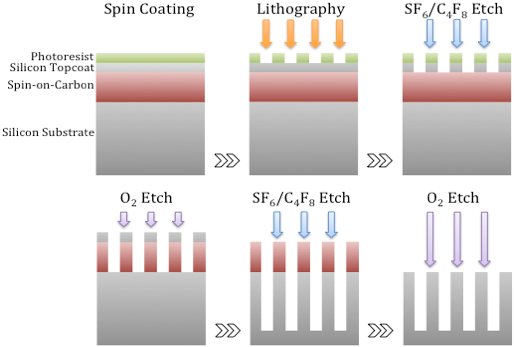

The figure on the right shows a typical tri-layer etch stack process and the amplification of achievable aspect ratio.

In a tri-layer etch stack the bottom layer is typically thick amorphous carbon deposited by chemical vapor deposition (CVD). The challenges for CVD are high capital and running costs, particle defects, and the non-planarizing nature of the layer.

Irresistible Materials’ innovative SOC materials are based on novel carbon fullerene derivatives. These outperform CVD and existing state-of-the-art materials across several critical performance metrics. Benefits include:

- High etch resistance

- High thermal stability

- High carbon content

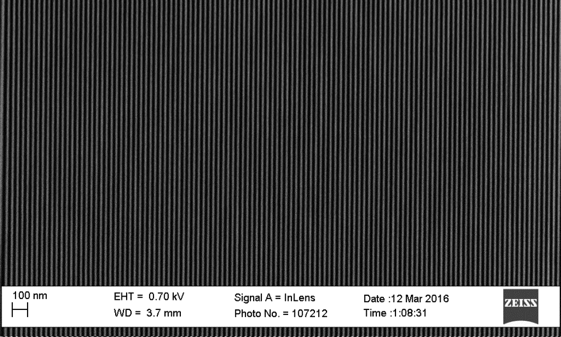

The image on the left shows 25nm half-pitch pattern transferred into one of IM’s leading SoC material formulations.

For further details on IM’s SoC material, please refer to our technology bulletin. [Coming Soon]